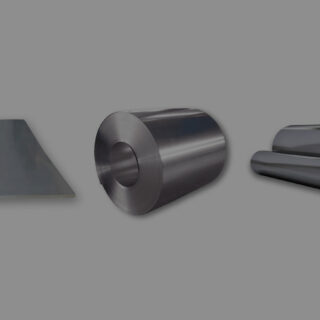

Duplex and super duplex stainless steels represent a significant advancement in metallurgical technology, combining favorable properties of both austenitic and ferritic stainless steel types. In this blog, we will delve into the Duplex super duplex category of steels, exploring their Alloy benefits, exceptional Corrosion resistant duplex properties, varied Duplex alloy grades, and Super duplex applications. As provided by Nufit Alloys, these materials offer superior strength and durability in challenging environments

Introduction to Duplex and Super Duplex Alloys

Duplex stainless steels are called duplex because they have a two-phase microstructure of grains of ferritic and austenitic stainless steel. The equivalent to duplex in this series is 25% chromium (%Cr), which is derived from the super duplex stainless steel, with the addition of higher amounts of Cr, Ni, Mo, and N for increased corrosion resistance and strength

Key Characteristics

- Strength : As already said duplex alloys have a higher strength level than conventional ferritic and austenitic stainless steels.

- Toughness and Durability : An excellent combination of strength and toughness whether and at what temperature.

- Corrosion Resistance : Great resistance to a large number of chemical attacks including chlorides and those from other harsh chemicals encountered in the marine environments

Applications of Duplex and Super Duplex Alloys

Super duplex applications span a variety of industries due to their robust properties. Here are some of the most significant applications

- Oil and Gas : Pipes, pumps, valves, and other equipment subjected to chemicals or high pressure.

- Desalination Plants : Perfect for high chloride atmospheres, hence they are very resistant to stress and suitable for components in reverse osmosis plants.

- Chemical Processing Industry : Reactors, heat exchangers, and tanks benefit most from high corrosion resistance.

- Marine Industry : Super duplex alloys are extensively utilized in shipbuilding and repair, especially in systems that come into contact with seawater

Nufit Alloys' Duplex Alloy Grades

Nufit Alloys provides a range of duplex and super duplex stainless steel grades, each tailored for specific applications and environments. These Duplex alloy grades include

- 2205 Duplex : Provides good oxidation and scaling resistance, along with high stress-corrosion cracking resistance.

- 2507 Duplex : Typically stronger than A7075 and excellent in pitting and crevice corrosion

Advanced Manufacturing Techniques and Custom Solutions

- Precision Engineering : Nufit Alloys, in its advanced facilities, makes use of precision engineering to manufacture duplex super duplex stainless steel materials with exact chemical composition and fine microstructures. What this does is enable uniform quality and performance levels across all applications.

- Custom Alloy Development : Nufit Alloys provides custom alloy development services but the company also understands that not all products are made with standard steel so they offer customized alloy manufacturing services to meet your needs. This versatility allows clients to request variations in the standard duplex and super duplex recipes to better facilitate specific environmental or mechanical stress requirements

Lifecycle and Environmental Impact

- Sustainability : Not only do we source our duplex and super duplex stainless steels from renewable resources, but these metals are also 100% recyclable. As a result, this lowers the overall environmental footprint and helps to meet sustainability targets for businesses such as construction and automotive. The recycling of materials is important in these industries; you can find out more about how wastewater is recycled here.

- Lifecycle Cost Analysis : These materials are more expensive at the outset, but over the life of a material can actually be more cost-effective on a lifecycle cost analysis basis simply because they will outperform other materials in terms of remaining life and maintenance requirements

Enhancing Safety and Compliance in Critical Industries

- Safety Standards : Duplex and super duplex stainless steels are manufactured to meet or exceed rigorous safety and quality standards. Nufit Alloys ensures that all their products comply with international safety standards such as ASTM, ISO, and ANSI, which is crucial for applications in sensitive and high-risk environments.

- Regulatory Compliance : For industries regulated under strict environmental and safety laws, using Nufit Alloys' duplex and super duplex stainless steels can help companies ensure compliance with environmental regulations, particularly those related to corrosion control and toxic substance containment

Future Trends in Alloy Use

- Growing Market Demand : The market for duplex and super duplex stainless steels is projected to grow significantly. This trend is driven by increasing demands in offshore oil drilling, desalination, and pollution control systems where superior corrosion resistance and strength are paramount.

- Technological Innovations : Ongoing research into improving the weldability and toughness of duplex and super duplex materials at extremely low or high temperatures could open new applications in aerospace and deep-sea exploration

Conclusion

Duplex and super duplex stainless steels from Nufit Alloys provide a potent combination of strength, corrosion resistance, and cost-effectiveness, making them ideal for a wide range of industrial applications. As industries continue to face more demanding environments and seek more sustainable and cost-effective materials solutions, the role of duplex and super duplex alloys will undoubtedly expand, offering new possibilities for efficiency and performance

Contact us at sales@nufialloys.com to learn more about how our Duplex and Super Duplex Alloys can enhance the safety, reliability, and efficiency of your systems