The oil and gas industry operates in some of the harshest environments on Earth, where equipment and infrastructure face relentless challenges from extreme pressures, corrosive substances, and fluctuating temperatures. To maintain safe and efficient operations, choosing the right materials is paramount. This is where duplex and super duplex alloys step in, offering a unique combination of strength, corrosion resistance, and cost-effectiveness that has revolutionized the industry

The Unforgiving Nature of Oil and Gas Operations

Oil and gas extraction and processing involve a wide range of demanding applications, each with its own set of material requirements

- Extreme Pressures : Deep-sea drilling, subsea pipelines, and high-pressure vessels all demand materials that can withstand immense forces without succumbing to deformation or failure.

- Corrosive Environments : Exposure to saltwater, sour gas (containing hydrogen sulfide), carbon dioxide, and other corrosive substances can rapidly degrade standard alloys, leading to leaks, equipment damage, and costly downtime.

- Temperature Fluctuations : From the frigid depths of the ocean to the scorching heat of deserts, equipment must maintain its integrity across a wide range of temperatures.

- Abrasion and Erosion : The constant flow of fluids, often containing abrasive particles like sand or drilling mud, can wear down components over time

Duplex and Super Duplex Alloys: Rising to the Challenge

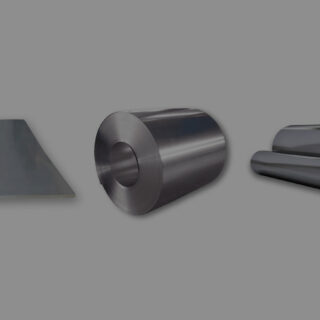

Duplex and super duplex stainless steels are a family of alloys that have emerged as the gold standard for tackling these challenges in the oil and gas industry

- Exceptional Strength : These alloys boast significantly higher yield and tensile strength than traditional austenitic stainless steels. This allows for the use of thinner-walled components, reducing material costs and weight while maintaining structural integrity.

- Outstanding Corrosion Resistance : Duplex and super duplex alloys exhibit remarkable resistance to a wide range of corrosive environments, including chloride-induced pitting, crevice corrosion, and stress corrosion cracking. This translates to longer-lasting equipment, reduced maintenance, and a safer working environment.

- Temperature Stability : These alloys retain their mechanical properties across a broad temperature range, making them suitable for both cryogenic and high-temperature applications.

- Wear and Abrasion Resistance : The high chromium and molybdenum content of duplex and super duplex alloys contributes to their exceptional wear and abrasion resistance, extending the lifespan of components in abrasive environments

Applications in the Oil and Gas Industry

Duplex and super duplex alloys are used extensively throughout the oil and gas value chain

- Drilling and Production : Risers, wellhead components, tubing, and downhole tools.

- Pipelines and Flowlines : Onshore and offshore pipelines, subsea flowlines, and umbilicals.

- Processing Equipment : Separators, heat exchangers, pumps, valves, and pressure vessels.

- Offshore Platforms : Structural components, firewalls, and seawater systems

Nufit Alloys: Your Trusted Partner for Duplex and Super Duplex Solutions

At Nufit Alloys, we’re dedicated to giving the oil and gas sector the best duplex and super duplex alloys possible, customized to meet their unique requirements. Our team of professionals works closely with clients to determine the best alloy for each application, considering the challenges faced by the industry. Our wide range of services, which includes bespoke fabrication, technical advising, and on-time delivery, guarantees that our clients get the assistance they require to get the most out of and prolong the life of their vital assets

Case Studies: Real-World Results

- Subsea Pipeline Success : A major oil and gas operator successfully deployed a super duplex pipeline in the harsh conditions of the North Sea. The pipeline has exceeded expectations in terms of corrosion resistance and reliability, reducing maintenance costs and ensuring a continuous flow of oil and gas.

- Offshore Platform Upgrade : By replacing aging carbon steel components with duplex stainless steel, an offshore platform extended the lifespan of its critical infrastructure, minimizing downtime and enhancing safety

Conclusion

Duplex and super duplex alloys have become indispensable in the oil and gas industry, enabling safer, more efficient, and more reliable operations in some of the most challenging environments on Earth. If you’re looking to optimize your oil and gas applications, Nufit Alloys is your trusted partner for high-performance duplex and super duplex solutions

Get in touch with Nufit Alloys at sales@nufialloys.com or contact Nufit Alloys to find out more about the advantages of Duplex and Super Duplex Alloys in Oil and Gas Applications