Hastelloy B2

Home > Nickel Alloys > Hastelloy B2

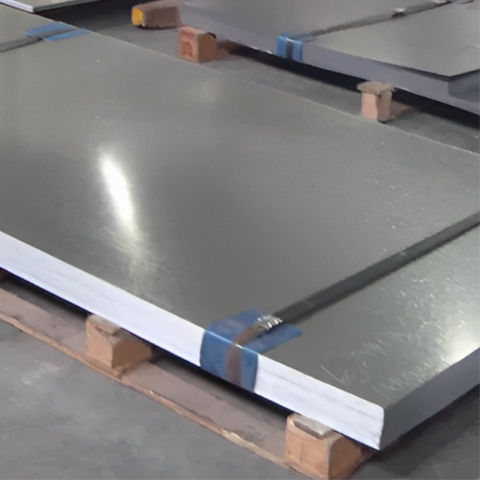

Hastelloy B2

Nufit Alloys is a well-known Importer, Stockist, and Supplier of Hastelloy B2 in Mumbai, India.. Our focus on consistent delivery and maintaining a large inventory sets us apart in terms of quality. We take pride in being a reliable partner that offers exceptional solutions to sectors that demand perfection. At Nufit Alloys, we have earned our reputation as an industry leader by placing emphasis on dependability. With our extensive inventory, we are able to promptly and efficiently meet the evolving needs of our customers in Mumbai and across the globe

Hastelloy B2 Importer, Nickel Alloy Supplier, Hastelloy B2 Stockist in Mumbai, UNS N10665 Stockist, Hastelloy B2 Importer in Mumbai, Hastelloy B2 Stockist, Hastelloy B2 Supplier in Mumbai

Hastelloy B2, which is a nickel-molybdenum alloy, has a remarkable ability to resist corrosion even in the most challenging conditions. It belongs to the robust Hastelloy alloy family and is specifically designed to withstand extreme environments, ranging from high temperatures to acidic solutions. Unlike its predecessor, Hastelloy B2 offers enhanced resistance against certain forms of corrosion

One of the key advantages of Hastelloy B2 is its suitability for chemistry applications without requiring post-weld treatment. This is due to its ability to prevent the development of grain boundary carbides in areas affected by welding heat. Additionally, this alloy demonstrates excellent corrosion resistance thanks to its low carbide and phase precipitation levels. With Nufit Alloys, industries gain access to a dependable supply of Hastelloy B2, ensuring optimal performance in corrosive environments

Hastelloy B2’s main characteristics include :

- Chemical Resistance: Hastelloy B2 exhibits exceptional resistance to a wide range of corrosive chemicals, making it suitable for harsh environments

- High Temperature Stability: With superior heat resistance, Hastelloy B2 maintains structural integrity and performance at elevated temperatures

- Excellent Weldability: This alloy offers ease of welding and fabrication, ensuring efficient joining processes for various applications

- Low Carbon Content: Hastelloy B2's low carbon composition enhances its corrosion resistance, particularly in reducing environments

- Outstanding Mechanical Properties: The alloy's robust mechanical strength contributes to its durability and suitability for challenging operational conditions

- Uniform Corrosion Resistance: Hastelloy B2 provides uniform protection against corrosion, ensuring consistent performance in aggressive chemical and high-temperature settings

Other Designations:

Hastelloy B2 is known by various trade names and designations- UNS N10665

- ASTM B335

- ASTM B335

Application

- Chemical Processing: Hastelloy B2 excels in chemical reactors, vessels, and piping systems, safeguarding against corrosion in demanding applications

- Pharmaceutical Equipment: Ideal for pharmaceutical manufacturing, B2's corrosion resistance ensures product purity and integrity in critical equipment

- Oil and Gas: Widely used in oil and gas extraction and processing due to its resilience against corrosive elements in harsh environments

- Pollution Control: Vital for pollution control systems, providing durability and corrosion resistance in scrubbers, stacks, and exhaust ducts

- Aerospace Components: With high-temperature stability and corrosion resistance, it is employed in aerospace components, ensuring reliability in extreme conditions

- Pulp and Paper Industry: Resistance to corrosive chemicals makes it a preferred choice in pulp and paper processing equipment, enhancing longevity and efficiency

- Seawater Applications: Suitable for marine environments, Hastelloy B2 is utilized in seawater desalination plants, offering corrosion protection in critical components

Fabrication of Hastelloy B2 :

Fabrication of Hastelloy B2 involves various methods such as cutting, forming, and welding, which allow for the creation of intricate components tailored to specific industrial needs. This ensures a quick and efficient production process

Cold Working of Hastelloy B2 :

When it comes to cold working, Hastelloy B2 demonstrates exceptional capabilities. It can be cold formed through bending and drawing without compromising its corrosion resistance or mechanical strength

Annealing for Hastelloy B2 :

To further enhance the mechanical properties and corrosion resistance of Hastelloy B2 after cold working, annealing is recommended. Annealing at temperatures ranging from 1950°F to 2050°F (1066°C and 1121°C) followed by rapid cooling helps achieve these desired qualities

Chemical Composition

| Element | Composition (%) |

|---|---|

| Nickel (Ni) | 68.0 min |

| Molybdenum (Mo) | 26.0-30.0 |

| Iron (Fe) | 2.0 max |

| Chromium (Cr) | 1.0 max |

| Silicon (Si) | 0.10 max |

| Carbon (C) | 0.02 max |

| Cobalt (Co) | 1.0 max |

| Manganese (Mn) | 1.0 max |

| Phosphorus (P) | 0.04 max |

| Sulfur (S) | 0.03 max |

Physical Properties

| Properties | Metric |

|---|---|

| Density | 9.2 g/cm³ |

| Melting Point | 1330-1380°C (2426-2516°F) |

| Thermal Conductivity | 10.7 W/m·K |

| Electrical Resistivity | 1.3 x 10⁻⁶ Ω·m |

Mechanical Properties

| Properties | Metric |

|---|---|

| Tensile Strength | 690 MPa (100,000 psi) |

| Yield Strength | 283 MPa (41,000 psi) |

| Elongation | 40% |

| Hardness (Brinell) | 217 HB |