Inconel 625

Home > Nickel Alloys > Inconel 625

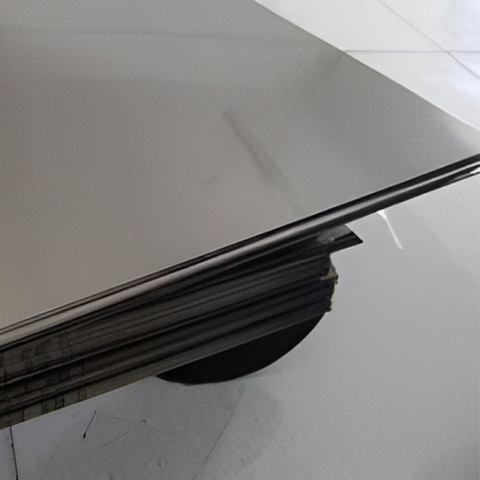

Inconel 625

Nufit Alloys has gained a reputation as the top stockist, supplier, and importer of the highly sought-after Inconel 625 in Mumbai, India. Our unwavering commitment to quality sets us apart as a reliable provider of this corrosion-resistant nickel-based alloy. At Nufit Alloys, we cater to diverse industrial requirements and guarantee a consistent supply of exceptional alloys, solidifying our position as the preferred choice for Inconel 625. With an extensive inventory and robust quality assurance practices, we give our valued customers confidence and satisfaction

Inconel 625 Importer, Nickel Alloy 625 Supplier, Inconel 625 Stockist in Mumbai, UNS N06625 Stockist, Inconel 625 Importer in Mumbai, Inconel 625 Stockist, Inconel 625 Supplier in Mumbai

Inconel 625, a resilient and corrosion-resistant nickel alloy with high strength, finds wide application in diverse industries. Composed of nickel, chromium, molybdenum, and niobium, it showcases exceptional fatigue and creep resistance. Suited for structural components exposed to cyclic loading and sustained high temperatures, Inconel 625’s weldability facilitates the production of intricate shapes and structures, making it a versatile choice for various manufacturing applications

This alloy’s versatility makes it suitable for structural components subjected to cyclic loading and sustained high temperatures. Nufit Alloys ensures the quality and reliability of Alloy 625, providing a robust solution for applications requiring both strength and resistance in challenging environments

Key characteristics of Inconel 625 include :

- Composition: Alloy 625 is a nickel-based superalloy (58% nickel) with added chromium, molybdenum, and niobium, providing exceptional strength and resistance to corrosion and oxidation

- Corrosion Resistance: Exceptional resistance to various forms of corrosion, including pitting, crevice corrosion, and stress-corrosion cracking

- High-Temperature Performance: Alloy 625 can withstand elevated temperatures up to approximately 1,000°C (1,832°F) without significant loss of mechanical properties

- Strength and Toughness: High tensile strength, good ductility, and impressive fatigue strength, ensuring reliability in demanding applications

- Weldability: Alloy 625 is readily weldable using various welding techniques, making it a versatile choice for fabricating complex components and structures

- Non-magnetic: Alloy 625 is non-magnetic in nature, which is beneficial in certain applications where magnetic interference is a concern

Other Designations:

Inconel 625 is known by various designations- UNS N06625

- Werkstoff Nr. 2.4856, among others

Application

Inconel 625 is extensively utilized for its exceptional properties, serving diverse applications across various domains due to its reliability and enduring performance

- Aerospace: Used in aircraft ducting systems, combustion chambers, and turbine shrouds due to its high-temperature stability and oxidation resistance

- Chemical Processing: Inconel 625 is employed in corrosive environments involving acids, alkalis, and salt solutions

- Marine Engineering: Its exceptional resistance to seawater corrosion makes it suitable for marine applications

- Oil and Gas: Inconel 625 is utilized in downhole and wellhead components due to its corrosion and stress cracking resistance

- Nuclear Power: Its mechanical properties and resistance to radiation-induced degradation are valuable in nuclear reactor environments

Fabrication of Inconel 625 :

Inconel 625, a superalloy, is created using procedures such as machining and welding. Because of its great strength and corrosion resistance, it is essential to utilize suitable ways to retain its qualities

Cold Working of Inconel 625 :

It involves deforming Inconel 625 at room temperature in order to increase its strength and hardness. Rolling and drawing are two common procedures for developing a fine-grained structure with superior mechanical characteristics

Annealing for Inconel 625 :

Annealing, a heat treatment procedure, is used on Inconel 625 to release tensions and restore ductility. The material is heated to a certain temperature and then progressively cooled, improving its microstructure for improved performance

Chemical Composition

Inconel 625’s chemical composition, including nickel, chromium, and other elements, provides high corrosion resistance and strength for various industrial applications

| Element | Content % |

|---|---|

| Nickel (Min) | 72 |

| Chromium | 14-17 |

| Iron | 6-10 |

| Carbon (Max) | 0.15 |

| Manganese (Max) | 1 |

| Sulfur (Max) | 0.015 |

| Silicon (Max) | 0.5 |

| Copper (Max) | 0.5 |

Physical Properties

The physical properties of Inconel 625, including density, melting and point, contribute to its durability and performance in extreme environments

| Properties | Metric |

|---|---|

| Density | 8.47 g/cm3 |

| Melting Point | 1290-1350°C (2354-2462°F) |

| Thermal Conductivity: | 9.8 W/m·K (100°C) |

| Electrical Resistivity: | 1.29 μΩ·m (20°C) |

Mechanical Properties

Inconel 625 exhibits impressive mechanical strength, with a high proof stress, ultimate tensile strength, and significant elongation for structural reliability

| Properties | Metric |

|---|---|

| Tensile Strength | 760 MPa (110,200 psi) (min.) |

| Yield Strength | 345 MPa (50,000 psi) (min.) |

| Elongation | 30% (min.) |