In the realm of industrial material science, Titanium alloys industrial have emerged as a cornerstone for a plethora of applications, primarily due to their unparalleled strength-to-weight ratio and exemplary corrosion resistance. Leading the charge in this innovative field, companies like Nufit Alloys are pushing the boundaries of what’s possible with these materials in industrial settings, thereby reshaping manufacturing processes and product development across various sectors

The Pivotal Role of Titanium Alloys in Modern Industries

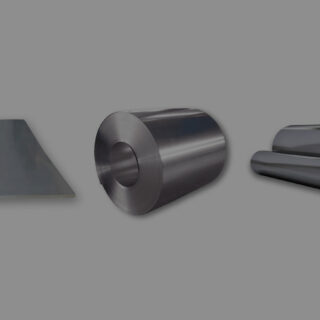

Titanium alloys industrial are not merely materials but revolutionary agents that drive modern industry. Their evolution is marked by significant technological advancements and enhanced application scopes. Industries ranging from aerospace to automotive, manufacturing, and even the biomedical fields rely heavily on titanium alloys for their unique capabilities. The Industrial applications titanium are extensive as these alloys provide critical benefits including high strength, light weight, and exceptional durability against environmental factors, making them indispensable in today’s technology-driven world

Cutting-Edge Advancements in Alloy Composition

One of the most exciting aspects of titanium usage in industry is the continuous innovation in alloy composition. Alloy innovation titanium has led to the development of High-strength alloys that cater to increasingly demanding applications. Nufit Alloys, for example, has developed proprietary titanium alloys that not only meet but exceed standard performance metrics such as increased tensile strength and improved thermal stability. These advancements allow industries to undertake more ambitious projects, secure in the knowledge that the materials they employ are up to the task

Unveiling the Multifaceted Benefits of Titanium Alloys

The Titanium alloy benefits are significant and multifaceted. Beyond their robustness, these alloys are remarkably resistant to a variety of corrosive agents, making them ideal for high-stress environments where lesser materials might succumb to wear and tear. Furthermore, their resistance to corrosion significantly extends the lifespan of products, ensuring sustainability and cost-effectiveness in long-term industrial projects. This durability also makes titanium alloys a preferred choice in marine, chemical processing, and even sports equipment industries, where reliability is paramount

Sustainability and Recycling Initiatives

One of the biggest advantages that the Titanium alloys industry possesses is its ability to be recycled and this can play a very significant part in creating sustainability by manufacturing. Titanium alloys are capable of being recycled an unlimited number of times without any substantial loss in quality or performance, which is not the case with several industrial materials. This will help us save more trees by minimizing the depletion of existing natural resources. Nufit Alloys is leading the way in advancing initiatives that not only enhance titanium recycling but also reduce waste and energy consumption from an array of industry sectors

Broader Industrial Applications of Titanium Alloys

Titanium alloy’s industrial applications are not limited to industries like aerospace and automotive, the utilization counts in rising markets that too outside traditional fields of activity. Titanium is being used to make components of wind turbines and solar panels in the renewable energy sector because it has a long-lasting lifecycle. Apart from that, the world of architecture is also using titanium as an aesthetic and structural building component which gives these buildings a highly durable element. The diversity of applications illustrates the potential for industrial-usage titanium in various industries while representing further growth within core markets

Exploring Future Directions and Innovations

Looking ahead, Alloy innovation titanium promises even more groundbreaking developments. With ongoing research into nanostructuring and alloy blending, the next generation of titanium alloys is expected to exhibit superior qualities. Innovations in how these materials interact at the atomic level could lead to even lighter, stronger, and more adaptable materials. This is not only beneficial from a materials science perspective but also essential for the broader goal of industrial innovation and environmental sustainability

Conclusion

The role of Titanium alloys industrial in shaping the future of numerous industries cannot be overstated. With visionaries like Nufit Alloys at the helm of Alloy innovation titanium, the potential for further advancements and applications is immense. As industries continue to evolve and demand materials that offer higher strength, better performance, and increased environmental resistance, titanium alloys stand ready to meet these challenges, reinforcing their position as a pivotal material in the vast landscape of industrial applications

Innovations spearheaded by companies like Nufit Alloys not only highlight the ongoing evolution and increasing importance of Titanium alloys industrial in global industrial applications but also underscore the profound impact that advanced material science can have on enhancing industrial capabilities and promoting sustainable practices worldwide

Contact us at sales@nufialloys.com to know more information about the Titanium Alloys, and how you can utilise them in industrial operations