In the intricate and demanding sectors of chemical industries and fertilizer industries, the selection of appropriate materials is of paramount importance. The harsh operational environments, characterized by corrosive chemicals, extreme temperatures, and high pressures, necessitate components with exceptional durability and resilience. Nufit Alloys recognizes the criticality of material selection in achieving operational excellence in these industries and offers Nitronic Alloys as a preferred solution. These high-performance austenitic stainless steels are uniquely engineered to meet the multifaceted demands of chemical and fertilizer production, thereby meeting demands of these challenging sectors. With Nufit Alloys at the forefront of providing solutions, the chemical and fertilizer industries can continue to thrive and innovate

Superior Material Properties for Demanding Applications

Nitronic Alloys, distinguished by their austenitic microstructure, possess a unique combination of properties that set them apart in chemical and fertilizer applications

- Enhanced Corrosion Resistance : Nitronic Alloys demonstrate remarkable resistance to a broad spectrum of corrosive media, including mineral acids, organic acids, alkalis, and chloride solutions. This makes them indispensable in the construction of process equipment, piping systems, and storage vessels.

- High Mechanical Strength : These alloys retain their structural integrity and mechanical strength even under elevated temperatures and pressures, ensuring the safe and reliable operation of critical components such as reactors, heat exchangers, and pressure vessels.

- Excellent Fabrication Characteristics : Nitronic Alloys exhibit good weldability and formability, enabling the fabrication of complex geometries and intricate designs tailored to specific process requirements

Tailored Solutions for Diverse Industrial Needs

Chemical Processing

- Reaction Systems : The heart of chemical processing often lies in reaction vessels, where raw materials undergo transformations to create desired products. Nitronic Alloys are frequently chosen for these vessels due to their exceptional corrosion resistance in the face of aggressive chemicals, such as acids, alkalis, and solvents. These alloys ensure the structural integrity of the reaction vessels, preventing leaks, contamination, and costly downtime.

- Heat Transfer Equipment : Efficient heat transfer is essential for many chemical processes. Heat exchangers, condensers, and reboilers are vital for heating, cooling, or condensing process fluids. Nitronic Alloys are well-suited for these applications because of their dual advantage

- Fluid Handling Systems : Chemical plants are intricate networks of pipes, valves, pumps, and other components that transport various fluids throughout the facility. Given the corrosive nature of many of these fluids, the use of Nitronic Alloys is widespread. The alloys ensure the reliability of these systems, preventing leaks and ensuring safe and efficient fluid transport

Fertilizer Production

- Ammonia Synthesis : Ammonia, a critical component of fertilizers, is synthesized through the Haber-Bosch process, a demanding procedure that requires specialized materials. Nitronic Alloys play a crucial role in this process due to their exceptional durability. Within the ammonia converter, where high temperatures and pressures prevail, these alloys resist the corrosive effects of the synthesis gas mixture, ensuring the vessel's structural integrity. Furthermore, Nitronic Alloys' high thermal conductivity and corrosion resistance make them ideal for heat exchangers, allowing efficient heat transfer and maintaining equipment longevity in this harsh environment.

- Urea Synthesis: Urea is another important fertilizer produced from ammonia and carbon dioxide. This process involves the formation and handling of corrosive carbamate solutions, along with high temperatures.

- Phosphoric Acid Production: Phosphoric acid, a key ingredient in phosphate fertilizers, is primarily produced through the wet process. This method involves the reaction of phosphate rock with sulfuric acid, creating a highly corrosive environment

Nufit Alloys: Your Strategic Partner

At Nufit Alloys, we recognize the criticality of material selection in achieving operational excellence in chemical and fertilizer plants. Our in-depth understanding of Nitronic Alloys, coupled with our unwavering commitment to quality and customer-centricity, positions us as your preferred partner in providing tailored solutions

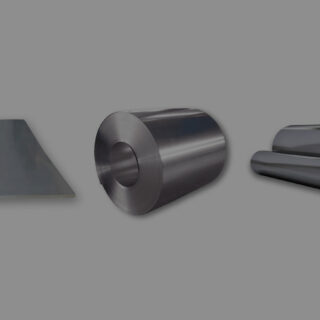

We offer a comprehensive range of Nitronic Alloy products, including plates, sheets, pipes, fittings, flanges, and bars, all conforming to international standards. Furthermore, our experienced engineers and technical experts are available to collaborate with you, providing material selection guidance, technical support, and customized solutions to optimize your operations

Contact us today at sales@nufialloys.com to explore how Nufit Alloys can empower your chemical or fertilizer processes with the superior performance of Nitronic Alloys