In the dynamic world of advanced manufacturing, materials play a pivotal role in determining the efficiency, reliability, and longevity of products. Among these materials, special alloys have emerged as game-changers, offering unparalleled thermal stability and mechanical strength. Nufit Alloys, a leading name in this sector, has been at the forefront of leveraging these advanced materials to drive innovation and excellence in manufacturing processes

Understanding Special Alloys

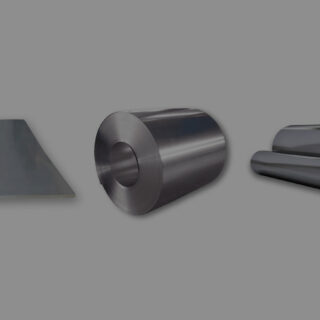

Special alloys are a subcategory of materials that are produced with the intention of having enhanced properties that cannot be obtained from ordinary metal. These alloys are developed to cater for the needs of harsh environments and applications which other materials cannot withstand. Special alloys’ composition may consist of base metals like nickel, titanium, and aluminum with additives like chromium, molybdenum, and vanadium. This leads to materials that can be used in environments that are extremely hot, corrosive, and mechanically stressful

Nufit Alloys: Pioneering Excellence

Nufit Alloys has become a market leader in the field of special alloys, setting high standards and constantly expanding the capabilities of these materials. Nufit Alloys’ solutions are centered on innovation and quality, and the company offers products for various sectors such as aerospace, automotive, energy, and medical applications. This policy makes it possible for the company to carry out research and development to enable it to be in a position to produce new products that will meet the needs of the industry as it grows and develop

The Importance of Thermal Stability

In most of the manufacturing processes, the materials used are subjected to high temperatures that may lead to their degradation. Some of the special alloys include those produced by Nufit Alloys and they are characterized by high thermal stability. For example, in aerospace industry, the parts like the turbine blades and the exhaust systems are exposed to high temperatures. Materials that find usage in these applications have to be strong and perform well without getting deformed or damaged

Thus, the products of Nufit Alloys are created to perform well in such conditions. These alloys also contain nickel and chromium and are thus highly resistant to thermal fatigue and oxidation. This helps to ensure that the components of the engine continue to work optimally without the need for replacement after a long time of use under high temperatures

Mechanical Strength: A Cornerstone of Durability

The second important characteristic of special alloys is their high mechanical properties. AM processes are typically used in highly stressed and loaded applications where the failure of a single component can cause a catastrophic failure. Special alloys, which offer higher tensile strength and toughness, offer the required durability to meet these demands

For instance in the automobile industry, special alloys are employed in fabrication of engine parts, transmission systems and suspension. These components must be able to withstand mechanical loads and vibrations throughout the structure’s lifetime. The materials used at Nufit Alloys are designed to perform well in such conditions and thus making vehicles safe and reliable

Case Study: Nufit Alloys in Action

For example, the use of Nufit Alloys’ special alloys in the manufacturing of energy equipment and facilities. Both conventional and renewable power plants are in need of materials that are capable of withstanding high temperatures and corrosive atmospheres. Nufit Alloys provides materials for parts like heat exchangers, boilers, and turbines which are essential in the functionality and durability of these plants

An example of this is the application of Nufit Alloys’ nickel based superalloys in the production of gas turbines. These turbines work at 1,000 degrees centigrade and are subjected to corrosive gases. These superalloys’ thermal stability and mechanical strength make the turbines to operate efficiently with little or no frequent maintenance hence cutting down the costs and increasing the performance of the power plants

The Future of Special Alloys in Advanced Manufacturing

As industries continue to evolve, the demand for high-performance materials will only grow. Special alloys will remain at the heart of advanced manufacturing, enabling the development of next-generation products and technologies. Nufit Alloys is poised to lead this charge, with a commitment to innovation, quality, and sustainability

The company’s focus on sustainable practices is particularly noteworthy. By developing alloys that enhance the efficiency and lifespan of products, Nufit Alloys contributes to reducing waste and minimizing environmental impact. This aligns with the broader trend towards sustainability in manufacturing, where companies are seeking ways to balance performance with environmental responsibility

Conclusion

The role of special alloys in advanced manufacturing cannot be overstated. Their unique properties, including exceptional thermal stability and mechanical strength, make them indispensable in a wide range of applications. Nufit Alloys, with its expertise and dedication to innovation, is a key player in this field, driving advancements that shape the future of manufacturing

You can Contact us at sales@nufialloys.com to learn more about Special alloys, and their applications in advanced manufacturing