In the realm of chemical processing, the choice of materials plays a crucial role in ensuring the efficiency, safety, and longevity of equipment and infrastructure. Among the many materials available, stainless steel alloys have emerged as indispensable in this industry. Their unique properties make them ideal for handling the rigorous demands of chemical processing environments

Understanding Stainless Steel Alloys

Stainless steel alloys are iron-based metals enhanced with a minimum of 10.5% chromium. This composition forms a passive layer of chromium oxide on the surface, which provides remarkable resistance to corrosion. Various other elements such as nickel, molybdenum, and nitrogen can be added to enhance specific properties. The versatility and adaptability of stainless steel alloys make them suitable for a wide range of applications in chemical processing

Corrosion Resistance: A Key Advantage

One of the most significant benefits of stainless steel alloys in chemical processing is their exceptional corrosion resistance. Chemical plants often deal with highly corrosive substances, including acids, bases, and solvents, which can severely damage standard metals. The corrosion-resistant nature of stainless steel alloys ensures that equipment remains intact and functional over extended periods, reducing maintenance costs and downtime

The ability to withstand corrosion is particularly vital in environments where the integrity of the material is paramount. For instance, in the production of pharmaceuticals, any contamination due to corrosion can compromise product quality and safety. Stainless steel alloys, with their robust corrosion resistance, provide a reliable solution to this challenge

High-Temperature Performance

Chemical processing often involves high-temperature reactions and processes. Stainless steel alloys are designed to maintain their mechanical properties and structural integrity at elevated temperatures. This makes them suitable for use in reactors, heat exchangers, and other equipment exposed to high thermal stress. The high-temperature performance of stainless steel alloys ensures that they can handle the demanding conditions of chemical processing without compromising on durability or safety

Hygienic and Cleanability Benefits

The hygienic properties of stainless steel alloys make them ideal for use in industries where cleanliness is critical. In chemical processing, especially in the pharmaceutical and food industries, maintaining a sterile environment is crucial to prevent contamination. Stainless steel’s smooth, non-porous surface prevents the buildup of bacteria and other contaminants, making it easier to clean and sanitize. This hygienic benefit is essential for complying with stringent industry standards and regulations

Versatility in Applications

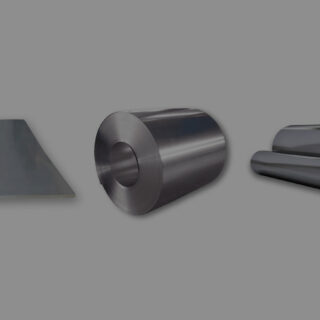

The versatility of stainless steel alloys is another reason for their widespread use in chemical processing. They are used in various applications, including storage tanks, piping systems, reactors, and heat exchangers. Their adaptability to different processing conditions and their ability to be fabricated into various shapes and sizes make them an ideal choice for custom equipment solutions

Moreover, stainless steel alloys are available in numerous grades, each tailored for specific environmental and operational conditions. For example, 316L stainless steel is widely used in chemical processing due to its enhanced resistance to chlorides and other corrosive agents. This versatility allows engineers to select the appropriate alloy that meets the specific requirements of their processes

Long-Term Cost Efficiency

While the initial cost of stainless steel alloys may be higher than some alternative materials, their long-term cost efficiency is unparalleled. The durability, corrosion resistance, and low maintenance requirements of stainless steel alloys translate into significant savings over the lifespan of the equipment. The reduction in downtime for repairs and replacements, coupled with the extended service life of stainless steel components, makes them a cost-effective investment for chemical processing facilities

Environmental and Safety Benefits

Stainless steel alloys contribute to environmental sustainability and safety in chemical processing. Their durability and resistance to corrosion reduce the need for frequent replacements, minimizing waste generation. Additionally, stainless steel is 100% recyclable, making it an eco-friendly material choice. The use of stainless steel alloys also enhances safety by ensuring that equipment remains robust and leak-free, preventing hazardous chemical spills and accidents

Conclusion

The role of stainless steel alloys in chemical processing cannot be overstated. Their unique properties, including exceptional corrosion resistance, high-temperature performance, hygienic benefits, versatility, and long-term cost efficiency, make them indispensable in this demanding industry. By choosing stainless steel alloys for chemical processing applications, companies can ensure the reliability, safety, and efficiency of their operations, ultimately contributing to their overall success

As a leading provider of high-quality stainless steel alloys, Nufit Alloys is committed to delivering materials that meet the stringent demands of the chemical processing industry. Our extensive range of stainless steel products is designed to provide superior performance and durability, helping our clients achieve their operational goals with confidence

You can Contact us at sales@nufialloys.com to know more information about Stainless Steel Alloys, and how they can be utilised in chemical processing