In the current world of industrial production, the choice of the materials to be used in the production process is very critical in determining the efficiency, durability and safety of production. From the many options that are available in the market, stainless steel alloys can be regarded as some of the best materials that can be used in various industries. However, what makes these alloys so special? In this blog, the author will explore the reasons that have placed stainless steel as one of the most reliable and quality metal in the industrial market especially in India

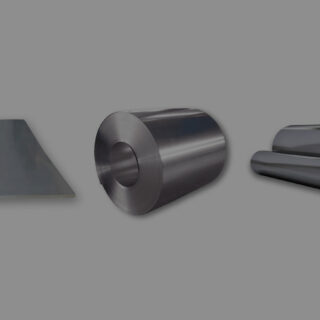

Understanding Stainless Steel: A Versatile Material

Stainless steel is a material which mainly consists of iron with a proportion of not less than 10%. 5% chromium. This composition enables the stainless steel to gain the special characteristic of not being easily corroded. But that is not all there is to it. They also possess other properties such as strength, ductility and can also withstand high temperatures. These characteristics make them useful in different fields including chemical processing industries, food industries among others

Stainless Steel Grades and Their Applications

Stainless steel is one of the most used materials in industry and one of the reasons is its versatility. There are many types of stainless steel and each is designed for particular uses. For example

- 304 Stainless Steel : This grade is referred to as the ‘general purpose’ of stainless steel and is highly corrosion resistant; it is used in kitchen appliances, production equipment and chemical vats.

- 316 Stainless Steel : It is quite well known for its resistance to chemical and salt water making it suitable for marine and chemical applications.

- 410 Stainless Steel : This grade offers high strength and wear resistance and is applied in items such as knives, tools and so on.

- 430 Stainless Steel : It is less corrosion resistant than 304 or 316 but cheaper and is used in automotive parts and home appliances

Why Stainless Steel Is the Go-To Material for Indian Industries

India, with its rapidly growing industrial sector, has seen an increasing demand for high-quality materials that can meet the challenges of modern manufacturing. Stainless steel has emerged as a material of choice for several reasons

- Corrosion Resistance : The climate of India is very severe and the used materials are exposed to varying levels of humidity, temperature and pollution. This makes stainless steel to be strong and durable since it does not corrode hence it will remain as it is even in the most severe conditions. This is especially so in such industries as chemical processing, oil and gas, and marine industries given the high risk of corrosion.

- Strength and Durability : There are many industries where it is required that the material used has to withstand a lot of stress and wear for a long time. Stainless steel is very strong and has a high level of resistance to corrosion; it is therefore used in industries like machinery manufacturing, construction and transport.

- Hygiene and Safety : Some of the industries that need high hygiene include the food processing industries, the pharmaceutical industries and the health care industries. It is an ideal material since it is non-porous and hygienic; cleaning it is also very easy, making it ideal for areas that demand high standards of hygiene.

- Sustainability : In the present world where people are more concerned with sustainability, stainless steel is recyclable material in the world. It has a very long life cycle and when it is recycled, it does not lose its quality and therefore is an environmentally friendly material for industries that are looking forward to minimizing their impacts on the environment.

- Heat Resistance : Some of the grades of stainless steel have the ability to work under high temperatures and can therefore be used in industries that require such materials as the aerospace industries, power generation industries and manufacturing industries.

- Aesthetic Appeal : Besides the functional properties, stainless steel has the aesthetic properties that are valued very much. The material is smooth and glossy and as a result it is used in construction and engineering and in the manufacture of high end goods. This appeal is not only aesthetic but also rational, as it indicates that only the best and the most durable materials are going to be used.

- Low Maintenance Costs : Stainless steel is a very strong material and also has a high level of resistance to corrosion and therefore it does not require frequent maintenance as compared to other materials. This leads to its being cheaper in the long run and thus is a cheaper method, especially for industries which may find it costly to maintain their machinery and buildings.

- Flexibility and Formability : Stainless steel is malleable and can be formed in various forms and hence it can be used in various sectors. Stainless steel can be manufactured in forms that include the following; sheets, bars, pipes, wires and many others depending on the requirement of the industry.

- Resistance to Impact and Mechanical Stress : Industrial conditions subject material to impact and mechanical stress. Stainless steel is tough and has the ability to resist shocks without bending or cracking hence suitable for mechanical and transport equipment as well as structures.

- Wide Availability : Stainless steel is available in the market and can be purchased from suppliers and distributors in India. This material is easily accessible to industries and this means that they can obtain the desired grades of the material without having to wait for long time which is important especially in industries in the process of regaining their operations

The Role of Stainless Steel Suppliers in Mumbai

Mumbai is one of the biggest industrial centers of India and it has a significant contribution in the supply and distribution of industrial stainless steel in the country. Mumbai-based stainless steel suppliers have the onus of making sure that the various industries in the country are supplied with the best stainless steel products. These suppliers not only offer various grades of stainless steel but also come up with the best solutions that will suit the needs of the various industries

Furthermore, Mumbai stainless steel distributors have gained credibility and experience in the market and therefore are the best approach for the material. From getting the right grade of stainless steel to getting it on time, these distributors are critical in the industrial development of India

The Future of Stainless Steel in Indian Industries

The future of stainless steel application is expected to be bright in Indian industries as the infrastructure of India is being developed and the industrial base is expanding. In construction and automotive, energy, manufacturing industries, and many others, stainless steel will remain to be the most preferred material due to its unique characteristics

Moreover, with the increasing focus on sustainable practices, stainless steel’s recyclability will become even more important. Industries will look to materials that not only perform well but also contribute to a circular economy. In this context, stainless steel’s role will only become more significant

Conclusion

Stainless steel alloys have proven time and again to be the best choice for industrial use, not just in India but globally. Their versatility, strength, durability, and resistance to corrosion make them ideal for a wide range of applications. As industries continue to evolve and face new challenges, stainless steel grades in India will remain at the forefront, supported by reliable suppliers and distributors, particularly in Mumbai

You can Contact us at sales@nufialloys.com to learn more about Stainless Steel Alloys and their role in high-temperature applications.