Whenever you imagine a naval ship cutting through the sea or a yacht smoothly sailing in a calm bay you can only wonder how such vessels are built. But what may not be quite as obvious is the fact that the material science which enables these vessels to float, work, and remain safe in even the most extreme of marine conditions. Integral to this is the application of stainless steel alloys—a material that is now favored in naval and marine industries. But why do these alloys shine in such conditions?

The Challenges of the Marine Environment

The ocean as we know is beautiful but is one of the harshest environments one can ever imagine. Sea water is aggressive and ships are in direct contact with it and other factors such as UV light, temperature, and physical abuse from waves and floating objects. These factors accumulate over time and result in the deterioration of the material used in the construction of the vessel, thus decreasing its durability, and increasing the frequency of maintenance

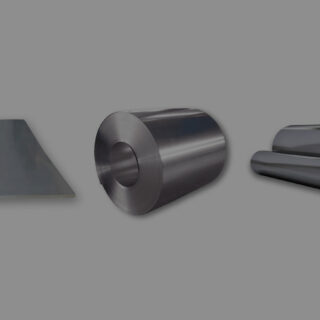

This is where stainless steel marine boats come into play. While other materials pose these challenges, stainless steel alloys are developed to handle them. Due to their composition, they are very immune to corrosion and this makes vessels to be in good condition for many years or even decades

Corrosion Resistance: The Key to Longevity

Among the various properties that make stainless steel alloys preferred in marine applications, the corrosion-resistant marine properties are the most important. In the marine environment, corrosion is very fast and the common type is galvanic corrosion where two dissimilar metals in contact with each other in an electrolyte solution such as seawater begin to corrode

Stainless steel alloys, particularly marine grade 316 stainless steel, are engineered to resist this type of corrosion. This is achieved through the addition of elements such as chromium, molybdenum, and nickel, which enhance the alloy’s resistance to the corrosive effects of seawater. The chromium forms a passive layer of chromium oxide on the surface, which prevents further corrosion by blocking oxygen diffusion to the steel surface. The addition of molybdenum in 316 stainless steel further increases its resistance to pitting and crevice corrosion, which are particularly problematic in chloride-rich environments like seawater

Strength and Durability

When it comes to naval and marine uses, strength and durability are two qualities that cannot be compromised. Ships and boats have to withstand the day-to-day pressure of being on the water, pressure from waves, pressure from floating objects, and the general wear and tear pressure of the day to day operations. Stainless steel alloys are therefore ideal for these applications because they are strong and at the same time flexible

Marine grade 316 stainless steel is especially popular for its tensile strength, which is the ability of a material to resist a force being applied to it without it bending or snapping. This makes it ideal for use in areas where failure is not acceptable such as in hulls, propellers, and fasteners

In addition, stainless steel has a long life span and thus does not need to be replaced as often as other materials, which saves time and money. For instance, other parts and components may require replacement or repair frequently because of rust or damage, while stainless steel parts may last for many years without requiring much attention

Versatility and Aesthetics

The other benefit of stainless steel alloys in marine use is that they are versatile. They can be bent to different shapes and forms, and used in different sizes on ships, boats and other marine applications. Stainless steel can be fabricated to create structures, fittings, and even ornaments because it can be shaped and formed in any way needed

Also, stainless steel has a sleek look that is appreciated in the design of luxurious yachts and other marine vehicles. It has a natural luster and does not tarnish, so it is used for visible parts where both aesthetics and functionality are considered

Environmental Considerations

In today’s world, environmental sustainability is a key consideration in any industry, and the marine sector is no exception. Stainless steel alloys are 100% recyclable, making them an environmentally friendly choice for shipbuilders and marine engineers. When a stainless steel component reaches the end of its life, it can be melted down and reused without losing its properties, reducing the need for new raw materials and minimizing waste.

Moreover, the longevity and durability of stainless steel mean that fewer resources are required over the lifetime of a vessel, further contributing to its sustainability. By choosing stainless steel, the marine industry can help reduce its environmental impact while still maintaining the highest standards of safety and performance.

Conclusion

The choice of materials in naval and marine applications is not one to be taken lightly. The harsh conditions of the marine environment demand materials that are not only strong and durable but also resistant to corrosion and environmentally sustainable. Stainless steel alloys, particularly marine grade 316 stainless steel, have proven time and again to meet these requirements, making them the preferred choice for shipbuilders and marine engineers around the world.

You can Contact us at sales@nufialloys.com to discover more about Stainless Steel Alloys, and their applications in naval and marine applications.